Hydrogen supply chain optimization is the process of organizing and managing the various processes involved in the production, distribution, storage, and transportation of hydrogen in the most cost-effective and efficient way possible. Finding and removing inefficiencies, bottlenecks, and other impediments that may impede the free flow of hydrogen across the supply chain is the process of optimization.

Download – https://www.marketsandmarkets.com/industry-practice/RequestForm.asp

The optimization of the hydrogen supply chain involves several stages, each with possibilities and challenges unique to itself. These stages include the following:

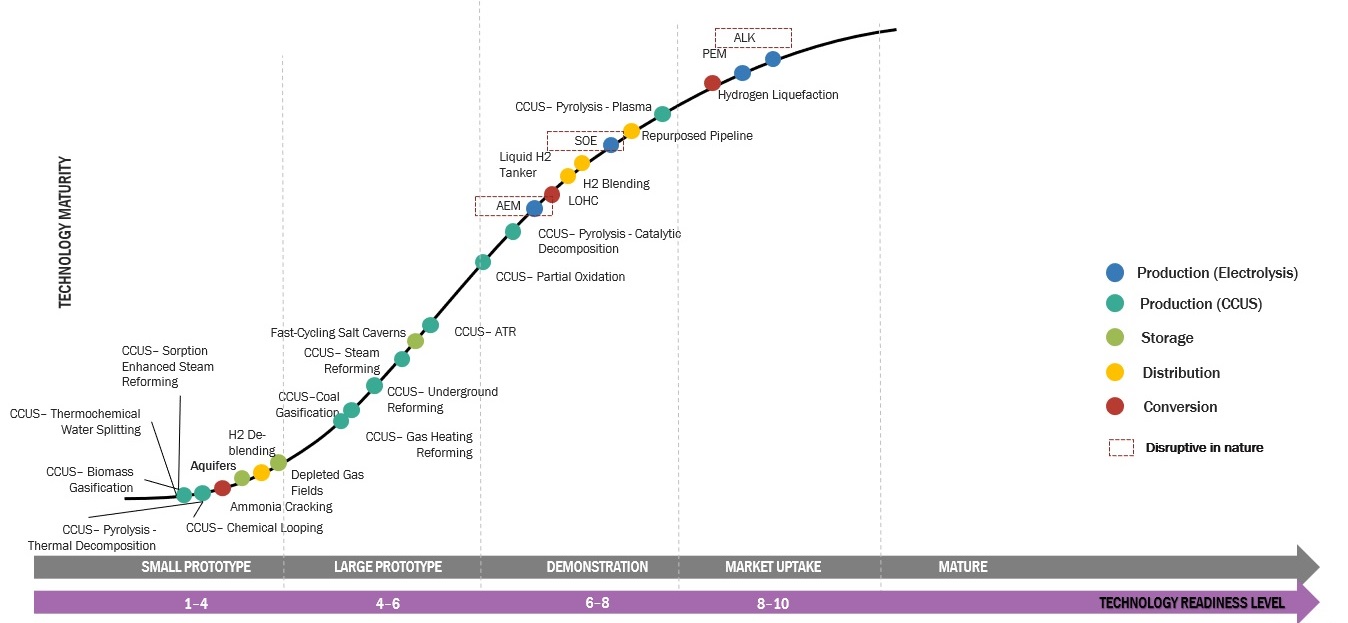

- Production: Hydrogen can be produced from water, natural gas, biomass, and other sources using a number of techniques such as electrolysis, steam methane reforming, and biomass gasification. The cost and availability of feedstock, the energy source, and other factors affect the production process selection. In order to maximize yield, the optimal feedstock and energy source must be selected, the production process must be improved, and production costs must be kept as low as possible.

- Storage and Transportation: When hydrogen is moved and stored, it is often either liquid or gaseous. The choice of storage and transportation methods is influenced by the volume, distance, required purity, and pressure of the hydrogen supply and demand sites. Optimizing hydrogen storage and transportation involves making the optimum technology choice, speeding the process for both storage and transportation, and cutting costs.

- Distribution: Hydrogen is transported to its final users, which include fuel cell vehicles, industrial applications, and the generation of power, by pipelines, trucks, or ships. The distribution method selection is influenced by the end-users’ location and volume as well as the required purity and pressure. Reducing distribution costs, optimizing the distribution process, and choosing the optimal distribution method are all necessary steps in enhancing hydrogen distribution.

In the end, each hydrogen process has advantages and disadvantages, and the choice of a certain technology depends on a variety of factors including cost, efficiency, environmental effects, feedstock availability, and infrastructure.

Hydrogen Energy Supply Chain

The Hydrogen Energy Supply Chain is the networked system of facilities and processes involved in the extraction, distribution, storage, and use of hydrogen as a source of energy. In this chain, the following components are typically present:

1. Production: Hydrogen can be produced by several techniques, such as steam methane reforming, electrolysis, and biomass gasification. Hydrogen is generated during the production stage using these sources.

2. Transportation: After manufacturing, hydrogen needs to be transported from the site to storage facilities or final consumers. There may be a mix of ways of transportation, including pipelines, ships, trucks, and others.

3. Storage: Depending on the infrastructure and application, hydrogen can be stored in a variety of ways, including liquid or gaseous form, ammonia, and solid-state storage systems.

4. Distribution: Storage facilities deliver hydrogen to final consumers, like manufacturing sites, power plants, and transit centers.

5. Utilization: Numerous end-user applications, such as power generation, fuel cell vehicles, industrial operations, and more, can benefit from hydrogen.

The goal of a hydrogen energy supply chain is to establish a seamless, efficient, and long-lasting infrastructure that enables the widespread use of hydrogen as a clean energy source. In order to guarantee hydrogen’s viability and competitiveness as an energy source, technological, financial, and regulatory challenges must be addressed along the whole supply chain.

Hydrogen Demand 2050

The global need for hydrogen as a feedstock or energy carrier in 2050 is anticipated or predicted, and is referred to as “Hydrogen Demand 2050“. Future energy scenarios and sustainability goals are common topics of discussion when it comes to this concept. When produced from a range of sources, including renewable energy, hydrogen is recognized as a clean, adaptable energy source that may be used in power plants, transportation, and many industries.

Hydrogen demand in 2050 is estimated taking into account a number of factors, such as:

1. Transition to Clean Energy: The goal of the world’s population to reduce greenhouse gas emissions and transition to a low-carbon or carbon-neutral energy system is expected to increase demand for hydrogen and other renewable energy sources.

2. Industry Transformation: Industries that produce steel, chemicals, and refinements using fossil fuels may convert to hydrogen to reduce their carbon footprint.

3. Transportation: Hydrogen may be used as a fuel by fuel cell electric vehicles (FCEVs), and as more countries explore for alternatives to internal combustion engines, the need for hydrogen in the transportation sector may increase.

4. Power Generation: Hydrogen fuel cells have the potential to generate electricity in power plants, especially when used in conjunction with one another. The industry that produces power may require more hydrogen as a result of a shift to more environmentally friendly energy sources.

5. Energy Storage: Hydrogen-based energy storage can help stabilize intermittent renewable energy sources. The amount of renewable energy sources in the energy mix may increase together with the need for hydrogen in energy storage applications.

The demand for hydrogen in 2050 is estimated by taking into account a number of factors, including economic growth, technological advancements, regulatory and legal frameworks, and the global commitment to addressing climate change. An estimated number may vary based on a variety of factors, including assumptions about how quickly energy is transitioning and how widely hydrogen technology will be adopted.

Read More – https://www.marketsandmarkets.com/industry-practice/hydrogen/hydrogen-supply-chain-optimization