Hydrogen Storage Solutions

Hydrogen storage is a crucial component of the hydrogen economy. Due to its low density and high flammability, hydrogen must be stored under high pressure, low temperature, or in a solid-state material. There are various hydrogen storage solutions available, and each has its own set of advantages and disadvantages. There are several hydrogen storage opportunities and technologies that have been explored:

1. Compressed Hydrogen Storage: Compressed hydrogen storage is the most common and widely used method of storing hydrogen. In this method, hydrogen gas is compressed and stored in high-pressure tanks. The tanks can be made from either metal or composite materials. Advancements in materials science and tank design have made this approach safer and more efficient. The storage pressure ranges from 350 to 700 bar, with higher pressures providing greater storage capacity.

2. Liquid Hydrogen Storage: Liquid hydrogen storage involves cooling hydrogen gas to its boiling point (-253°C) to liquefy it, after which it is stored in insulated tanks. Liquid hydrogen storage provides a higher energy density compared to compressed hydrogen storage. Hydrogen can be liquefied at extremely low temperatures (-253°C or -423°F).

3. Metal Hydride Storage: Metal hydride storage involves the use of metal alloys that can absorb and release hydrogen gas. The metal alloys are usually made from lightweight metals such as magnesium, titanium, or aluminum. The advantages of metal hydride storage include high storage capacity, safety, and low-pressure operation.

4. Chemical Hydrogen Storage: Chemical hydrogen storage involves the use of chemical compounds that can release hydrogen gas upon activation. The compounds can be organic or inorganic, and they include formic acid, ammonia borane, and sodium borohydride. Chemical hydrogen storage is suitable for portable devices, small fuel cells, and backup power systems.

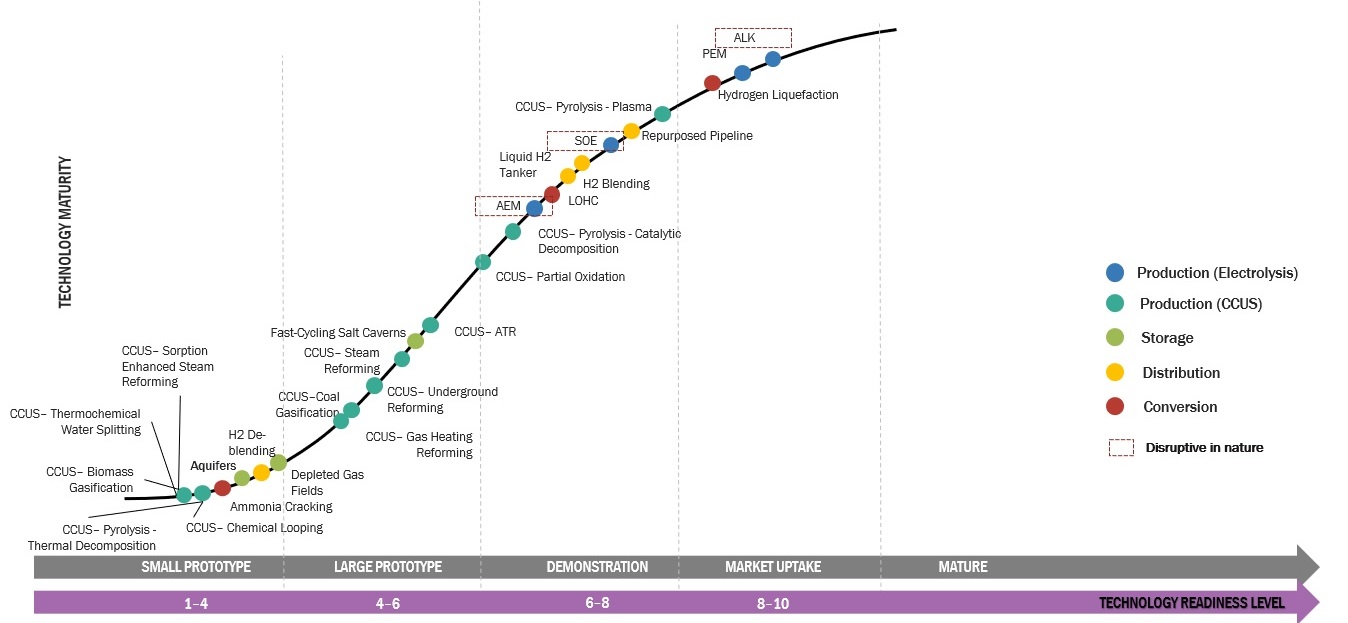

5. Underground Storage: Underground salt caverns and depleted natural gas reservoirs can be repurposed for hydrogen storage. Hydrogen is injected and withdrawn from these storage sites as needed.

Each of these opportunities has its advantages and challenges, and the choice of hydrogen storage method often depends on the specific application, scale, and safety considerations. Additionally, ongoing research and development aim to make hydrogen storage more efficient, cost-effective, and sustainable.

Download- https://www.marketsandmarkets.com/industry-practice/RequestForm.asp

Hydrogen storage has been one of the major technical challenges in the widespread adoption of hydrogen as a fuel source. Some of the key hydrogen storage problems include:

1. Low Energy Density: Hydrogen has a low energy density by volume compared to conventional fuels like gasoline and diesel. This means that in applications where space is limited, such as onboard vehicles, larger tanks or storage systems are required to store a sufficient amount of hydrogen to achieve a similar range or energy output.

Addressing this issue involves either developing more efficient storage methods or finding ways to improve the energy density of hydrogen carriers like metal hydrides or liquid organic hydrogen carriers (LOHCs).

2. High-Pressure Storage: To achieve a practical energy density, hydrogen needs to be stored at extremely high pressures, typically in the range of 350 to 700 bar (5,000 to 10,000 psi). This high-pressure storage can be a safety concern due to the risk of leaks, ruptures, and explosions.

Solutions include developing advanced composite materials for high-pressure tanks, stringent safety standards and regulations, and implementing safety measures such as pressure relief devices and hydrogen sensors.

3. Cryogenic Storage: Cryogenic storage, which involves cooling hydrogen to extremely low temperatures (-253°C or -423°F) to achieve a liquid state, is energy-intensive and requires specialized infrastructure.

The complexity and cost of cryogenic storage can be mitigated through advancements in cryogenic technologies and improved insulation materials for tanks, but it remains a challenge, particularly for small-scale applications.

4. Material Compatibility: Hydrogen can cause embrittlement in certain metals and can also permeate through materials like steel. This can lead to structural integrity issues and reduce the lifespan of storage tanks and pipelines.

Overcoming this challenge involves the development of hydrogen-compatible materials, coatings, and liners for storage systems. Research into materials like carbon-fiber-reinforced composites, polymers, and specialty alloys is ongoing.

5. Cost: The cost of hydrogen storage systems remains relatively high compared to other energy carriers, partly due to the specialized materials and technologies required for high-pressure or cryogenic storage.

Cost reduction strategies include economies of scale, advances in manufacturing processes, and research into innovative materials that offer both high performance and affordability.

Read More- https://www.marketsandmarkets.com/industry-practice/hydrogen/hydrogen-storage-solution