The process of planning and overseeing the many tasks involved in the production, distribution, storage, and transportation of hydrogen in the most economical and efficient manner is known as Hydrogen Supply Chain optimization. Optimization is the process of locating and fixing inefficiencies, bottlenecks, and other obstacles that can prevent hydrogen from moving freely throughout the supply chain.

Download – https://www.marketsandmarkets.com/industry-practice/RequestForm.asp

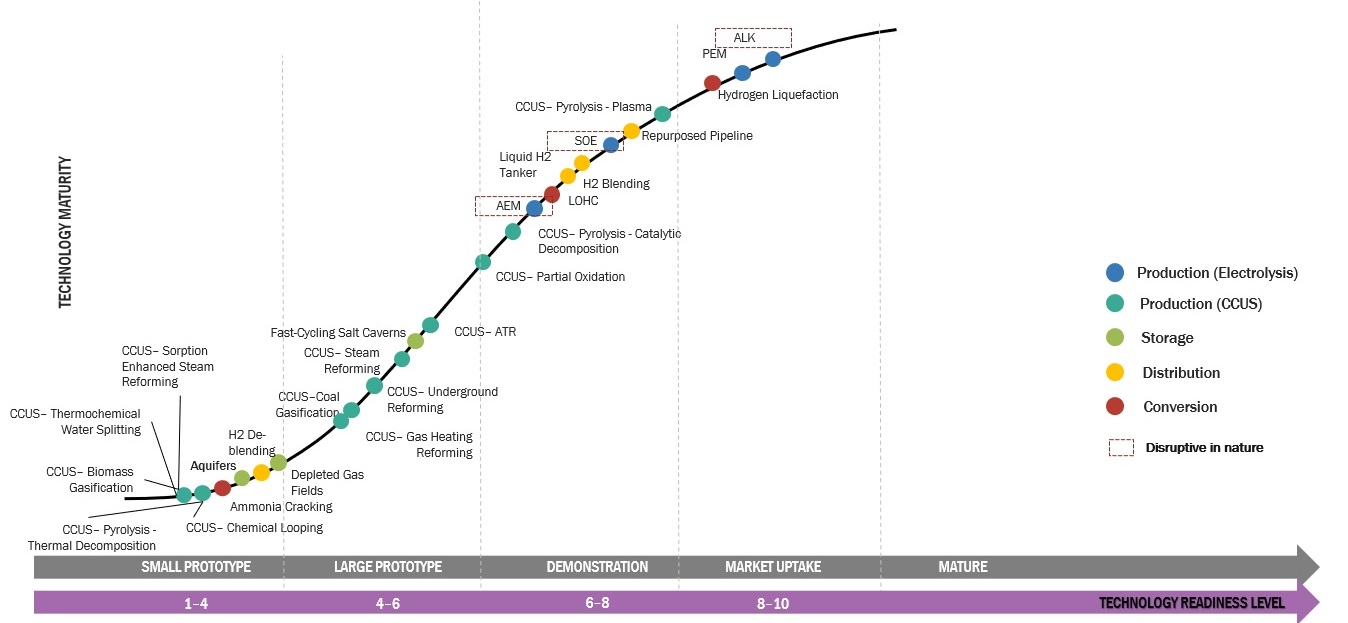

There are various stages to the hydrogen supply chain optimization, and each one has its own potential and obstacles. These phases consist of:

- Production: Biomass gasification, electrolysis, steam methane reforming, and other processes can all be used to manufacture hydrogen from a variety of sources, including water, natural gas, and biomass. Availability and cost of feedstock, energy supply, and other considerations influence the choice of production process. The best possible feedstock and energy source must be chosen, the production process must be optimized, and production costs must be kept to a minimum in order to maximize yield.

- Storage and Transportation: Generally, hydrogen is either gaseous or liquid when it is stored and transferred. The volume, distance, and necessary purity and pressure of hydrogen supply and demand locations all influence the storage and transportation method selection. Choosing the best technique for storage and transportation, streamlining the procedure for storage and transportation, and reducing expenses are all part of optimizing hydrogen storage and transportation.

- Distribution: Pipelines, trucks, or ships carry hydrogen to the final consumers, which include fuel cell cars, industrial uses, and electricity production. The volume and location of the end consumers, together with the necessary purity and pressure, all influence the distribution method selection. The process of improving hydrogen distribution entails determining the best distribution strategy, streamlining the distribution procedure, and reducing distribution expenses.

Ultimately, every hydrogen method possesses pros and cons, and the selection of a particular technology is contingent upon a multitude of aspects such as budget, effectiveness, ecological implications, feedstock accessibility, and infrastructure.

Hydrogen Energy Supply Chain

The networked system of facilities and procedures involved in the extraction, distribution, storage, and application of hydrogen as an energy source is known as the Hydrogen Energy Supply Chain. The following essential elements are usually present in this chain:

1. Production: Many processes, including biomass gasification, electrolysis, and steam methane reforming, can produce hydrogen. Using these sources, hydrogen is produced during the production phase.

2. Transportation: Hydrogen must be delivered from the production site to storage facilities or end users after it is produced. Transportation modes such as trucks, ships, pipelines, and others may be involved.

3. Storage: The storage of hydrogen can take different forms, such as solid-state storage devices, ammonia, or gaseous or liquid hydrogen, based on the infrastructure and application.

4. Distribution: Storage facilities transfer hydrogen to end users, such as factories, power plants, and transportation hubs.

5. Utilization: Hydrogen finds utility in a multitude of end-user applications, including industrial processes, fuel cell cars, power generation, and more.

Establishing a smooth, effective, and long-lasting system is the aim of a hydrogen energy supply chain, which facilitates the broad use of hydrogen as a clean energy source. To ensuring that hydrogen is a viable and competitive energy source, this entails tackling technological, financial, and regulatory issues at every point in the supply chain.

Hydrogen Demand 2050

The term “Hydrogen Demand 2050” describes the expected or predicted worldwide demand for hydrogen in 2050 as a feedstock or energy carrier. This idea is frequently brought up in relation to sustainability objectives and potential future energy scenarios. Hydrogen is regarded as a flexible and clean energy source that can be created from a variety of sources, including renewable energy, and utilized in industries, power plants, and transportation.

The estimation of the demand for hydrogen in 2050 considers various aspects, including:

1. Transition to Clean Energy: The global community’s desire to cut greenhouse gas emissions and move toward a low-carbon or carbon-neutral energy system is predicted to drive up demand for renewable energy sources like hydrogen.

2. Industry Transformation: Industries that use fossil fuels for things like chemical manufacture, steel production, and refining might switch to hydrogen in order to cut down on their carbon impact.

3. Transportation: Fuel cell electric vehicles (FCEVs) may use hydrogen as a fuel, and as more nations look for alternatives to internal combustion engines, the need for hydrogen in the transportation industry may grow.

4. Power Generation: Power plants can produce electricity using hydrogen as a fuel, particularly when hydrogen fuel cells are employed in tandem. A move toward greener energy sources can result in a rise in the need for hydrogen in the electricity producing industry.

5. Energy Storage: Energy storage using hydrogen can aid in balancing intermittent renewable energy sources. The need for hydrogen in energy storage applications can rise in tandem with the proportion of renewable energy sources in the energy mix.

Technological developments, legal and administrative frameworks, economic considerations, and the worldwide commitment to combating climate change are all taken into account when estimating the demand for hydrogen in 2050. Estimates can change depending on many circumstances and presumptions regarding the rate of the energy transition and the global uptake of hydrogen technology.

Read More – https://www.marketsandmarkets.com/industry-practice/hydrogen/hydrogen-supply-chain-optimization