In the realm of modern transportation, the pivotal role of materials like Stainless Steel 304 Tubing cannot be overstated. This grade of stainless steel tubing has become an indispensable element in various modes of transport, owing to its exceptional properties of durability, corrosion resistance, and adaptability.

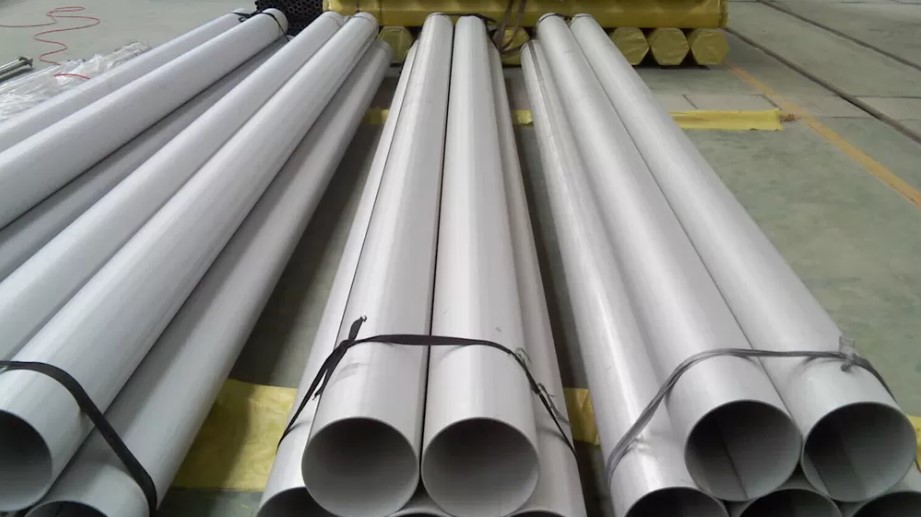

Unveiling Stainless Steel 304 Tubing

Stainless Steel 304, an austenitic alloy comprising chromium, nickel, and a small percentage of carbon, serves as the foundation for SS 304 Tubing. The alloy’s composition provides a unique set of attributes that have positioned it as a cornerstone material in the transportation sector.

1. Corrosion Resistance

Stainless Steel 304 Tubing’s innate ability to resist corrosion ensures its resilience against environmental elements, chemicals, and fluctuating weather conditions, ensuring longevity and reliability in transportation systems.

2. Strength and Durability

Renowned for its robustness, this grade of stainless steel maintains structural integrity even under demanding conditions, contributing to the longevity and reliability of transportation components.

3. Formability and Adaptability

The malleability of 304 Stainless Steel Tubing allows for diverse shaping and sizing options, catering to the specific needs of various transportation applications, and facilitating intricate designs and adaptations.

4. Resistance to High and Low Temperatures

Capable of withstanding extreme temperature variations without compromising structural integrity, making it ideal for transportation systems operating in diverse climates.

Applications Across Transportation Modes

1. Automotive Industry

Stainless Steel 304 Tubing plays a vital role in the automotive sector, employed in exhaust systems, structural components, and hydraulic lines, benefiting from its resistance to corrosion and ability to endure heat.

2. Aerospace Sector

In the aerospace industry, the tubing’s lightweight nature, combined with its durability and resistance to high temperatures, contributes to various critical components in aircraft systems.

3. Marine Transport

Utilized in marine environments due to its corrosion resistance, Stainless Steel 304 Tubing contributes to the construction of boat railings, hydraulic systems, and marine engines.

4. Railway Systems

In railway transportation, the tubing finds application in braking systems, structural components, and hydraulic lines, owing to its resilience and durability.

Advantages Paving the Way for Transportation Innovations

- Reliability: The consistent performance and durability of Stainless Steel 304 Tubing ensure the seamless operation of critical transportation systems.

- Adaptability: Ease of customization caters to the intricate and specific needs of diverse transportation applications, contributing to innovative design solutions.

- Safety Assurance: Resilience against corrosion and temperature variations guarantees the safety and integrity of essential transportation components.

- Cost-Efficiency: Longevity and minimal maintenance translate to significant cost savings across the transportation industry.

Conclusion: Stainless Steel 304 Tubing – A Driving Force in Transportation Evolution

Stainless Steel 304 Tubing stands as a testament to the fusion of durability, adaptability, and reliability within the transportation landscape. Its ubiquitous presence across diverse transportation modes underscores its pivotal role in facilitating innovation and progress.

As transportation technology continues to advance, Stainless Steel 304 Tubing’s unmatched properties will remain instrumental, fortifying advancements and contributing to the evolution of transportation systems worldwide. Its unwavering ability to ensure efficiency, reliability, and durability cements its indispensable status in the ongoing narrative of transportation innovation.