API 5L, or American Petroleum Institute Specification 5L, is a widely recognized standard for seamless and welded steel pipes transporting natural gas, oil, and other fluids. This blog explores API 5L pipes‘ significance, types, and key features.

Types of API 5L Pipe

API 5L pipes come in various types, with the most common ones being:

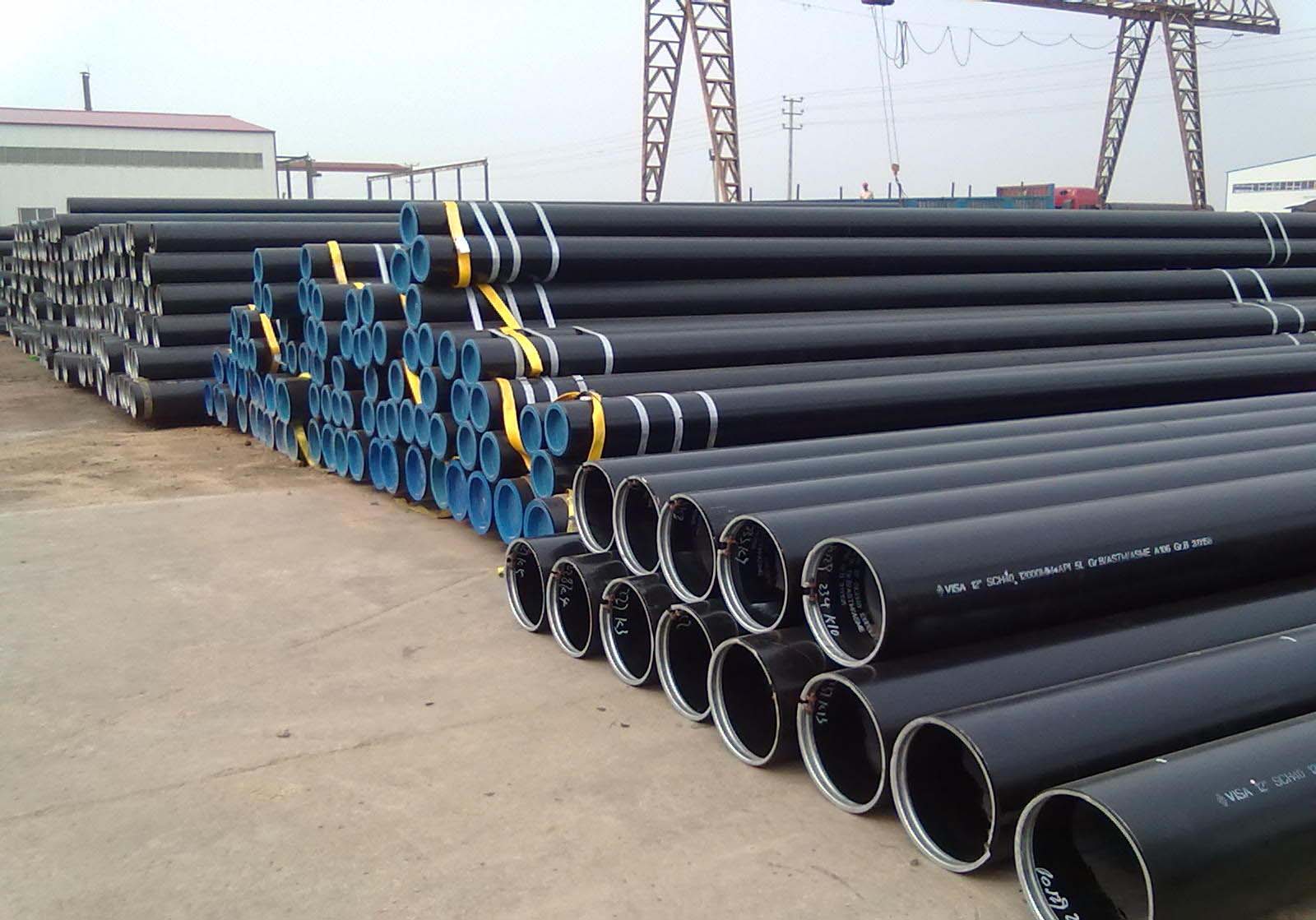

- API 5L Seamless Pipe: These pipes are manufactured without welding and are ideal for high-pressure applications. They are known for their uniform strength and durability.

- API 5L Welded Pipe: Welded pipes are constructed by welding the edges of steel plates or coils, making them suitable for less critical applications. They are more cost-effective and readily available.

- API 5L Line Pipe: This category is designed to convey gas, water, or oil in the oil and natural gas industries. The pipes are available in different grades, such as API 5L X52 and X60, each with specific mechanical and chemical properties.

Key Features of API 5L Pipe

API 5L pipes offer several essential features, making them a preferred choice in the industry:

- High Strength: API 5L pipes have high tensile strength, which allows them to withstand extreme pressure and stress.

- Corrosion Resistance: These pipes are typically coated with anti-corrosive materials, ensuring a longer lifespan and minimal maintenance.

- Dimensional Accuracy: They are manufactured to precise dimensions, reducing the risk of leakage or inefficiency in fluid transportation.

- Variety of Grades: API 5L offers a range of grades suitable for different applications, allowing for flexibility and customization.

In conclusion, API 5L pipes play a critical role in the transportation of fluids in the oil and gas industry. Understanding these pipes’ types and key features is essential for choosing the right one for your specific needs.