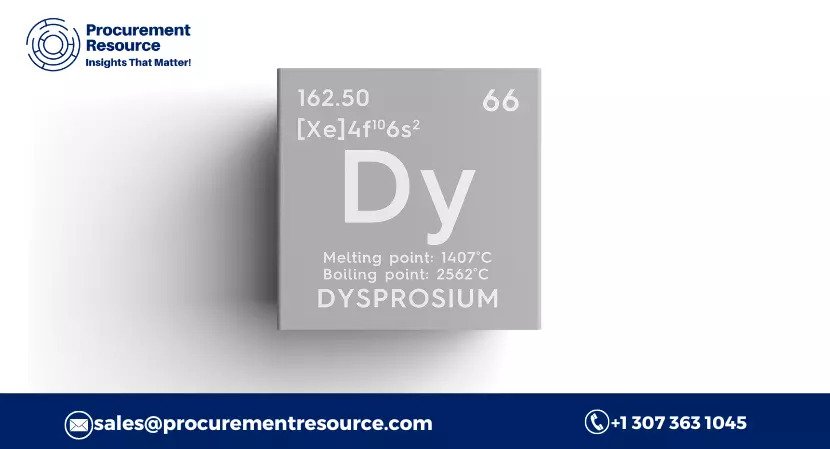

In the world of rare earth elements, dysprosium stands out for its significant application in high-tech industries. Dysprosium is a critical component in the manufacturing of magnets used in electric vehicles, wind turbines, and various technological advancements. To comprehend the dynamics and nuances of dysprosium production, a thorough understanding of the associated cost analysis becomes imperative.

Procurement Resource Assessment of Dysprosium Production Process

The procurement resource assessment of dysprosium production involves a comprehensive evaluation of the raw materials, equipment, labor, energy consumption, and other resources essential for the extraction and refinement of dysprosium. This assessment delves into the sourcing of rare earth ores, the processing facilities required, and the logistical needs, offering a detailed view of the procurement landscape. Understanding this process aids in determining the feasibility and cost-effectiveness of dysprosium production.

Product Definition

Dysprosium, a rare earth element, is often obtained through mining and then subjected to complex extraction and refining processes. The end product, dysprosium oxide or dysprosium metal, is utilized in various applications, predominantly in the manufacturing of high-strength permanent magnets, vital for green technologies, including electric vehicles and wind turbines. The product definition delineates the different forms and grades of dysprosium obtained and their distinct applications in industries.

Request For Free Sample: https://www.procurementresource.com/production-cost-report-store/dysprosium/request-sample

Market Drivers

The market drivers for dysprosium production encompass a myriad of factors influencing its demand, supply, and consequently, the cost analysis. Factors such as technological advancements, global shifts towards renewable energy, geopolitical influences on rare earth mining, and industry-specific demands significantly impact the market for dysprosium. Analyzing these drivers aids in predicting market trends, enabling better-informed business decisions.

Understanding Dysprosium Production Expenses

Dysprosium production expenses cover a broad spectrum, including mining costs, extraction, refining, energy consumption, labor, transportation, and regulatory compliance. A detailed understanding of these expenses is crucial for businesses involved in the dysprosium market. By meticulously analyzing the cost structures, companies can optimize their production processes, improve efficiency, and make informed pricing decisions.

Looking for an Exhaustive and Personalized Report that Could Substantiate Your Business

For businesses involved in dysprosium production or reliant on dysprosium-based products, an exhaustive and personalized cost analysis report is invaluable. Such a report offers tailored insights into the specific operational and financial aspects, providing a comprehensive understanding of the cost dynamics. This in-depth analysis helps in strategizing production, budgeting, and making informed investment decisions.

In conclusion, dysprosium, with its pivotal role in technological advancements, necessitates a comprehensive understanding of its production cost analysis. A well-structured report encompassing procurement resources, product definitions, market drivers, production expenses, and personalized insights is instrumental for businesses aiming to thrive in the dysprosium market.

Would you like to know more about specific elements of dysprosium production or further details regarding the cost analysis? If you’re looking for additional information, feel free to inquire further for a more in-depth understanding of this subject.