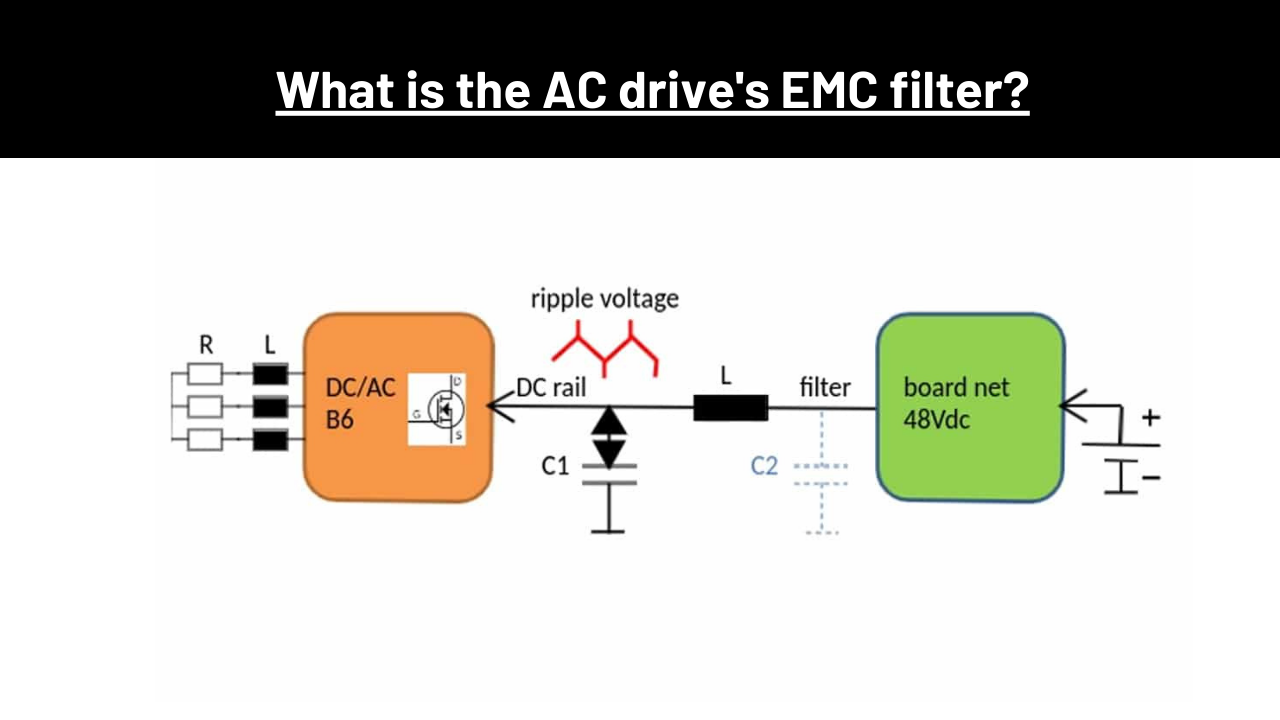

An EMC (Electromagnetic Compatibility) filter, also known as a line filter or a power line filter, is a crucial component of an AC drive system. By altering the frequency and voltage of the electrical current supplied to the motor, AC drives, sometimes referred to as variable frequency drives (VFDs) or inverters, regulate the speed and torque of AC motors.

The EMC filter is responsible for reducing electromagnetic interference (EMI), therefore the Allen Bradley PowerFlex AC drives must abide by electromagnetic compatibility regulations. Its purpose is to reduce the noise level of the AC drive’s electrical output and prevent it from reverberating or radiating into the power supply network or other adjacent electronic equipment.

Below is a list of an EMC filter’s primary functions in an AC drive system.

1. EMI Suppression:

High-frequency electrical noise produced by the AC drive is muted by the filter. Other electronic gadgets, communication systems, and neighbouring equipment may all experience issues as a result of this noise. The noise’s amplitude is decreased by the EMC filter, which also stops it from travelling via the power supply cables.

- EMI Filters: EMI filters, like the EMC filter in an AC drive system, are designed to lessen or filter out unwanted high-frequency noise generated by electrical equipment. These filters are put into the electrical circuitry to reduce the amplitude of electromagnetic emissions and prevent them from propagating via the power supply lines.

- Shielding: Sensitive electronic systems or components are protected by conductive enclosures or shields to block or direct electromagnetic radiation. By containing emissions, shielding prevents EMI from external sources and prevents emissions from interfering with nearby equipment. Materials like as metal or conductive composites can be used to build it.

2. Conducted EMI Mitigation:

The filter reduces electromagnetic interference that is conducted in both common and differential modes. Differential-mode noise happens in between the power supply lines, whereas common-mode noise is present on both power supply lines with respect to ground. The filter keeps the undesired noise away from the power source and shields other equipment from harm by functioning as an impedance to it.

- Common-Mode Chokes: Common-mode chokes, also known as common-mode filters or baluns, are used to lower common-mode conducted electromagnetic interference (EMI). Common-mode noise is the term used to describe unwanted electrical noise that appears on both power supply lines with respect to ground. Common-mode chokes are made by wrapping two windings around a magnetic core. By providing a high common-mode noise impedance, they mitigate the impact on the connected equipment.

- Grounding and Bonding: Adherence to appropriate grounding and bonding protocols is necessary for EMI mitigation. Delicate circuits can be protected against unwanted electrical currents and noise by establishing a low-impedance path to ground. Component bonding and grounding techniques help to provide a reliable system reference point and reduce the possibility of EMI issues.

3. Compliance with EMC Standards:

EMC standards like IEC 61800-3 and EN 55011 specify the maximum amounts of conducted and radiated emissions that are permitted in electrical equipment. An EMC filter helps the AC drive system comply with these standards by reducing the EMI produced by the drive and making sure it stays within the permitted limits.

- Emission Limits: EMC guidelines provide maximum acceptable emission levels for specific frequency bands. These limitations ensure that the devices do not release excessive electromagnetic radiation that might interfere with nearby electronic equipment or communication networks. Emission testing is done to measure the conducted and radiated emissions of a device and compare them to the specified constraints.

- Immunity Requirements: EMC standards also specify the immunity level that electronic equipment need to have against external electromagnetic disturbances in order to operate correctly. Immunity is necessary against a variety of disturbances, including conducted disturbances, radiated electromagnetic fields, electrostatic discharge (ESD), and brief transient bursts. Tests for immunity are performed to determine if a gadget can withstand such disruptions without breaking down or performing poorly.

Check: Allen Bradley PowerFlex 523 AC Drive

4. Protection of the AC Drive:

The AC drive is protected from potential transients and electrical noise in the power supply network by the EMC filter. By reducing these disturbances, the filter ensures that the reliability and performance of the AC drive are unaffected.

- Overcurrent Protection: AC drives include built-in overcurrent protection to stop excessive current from flowing between the drive and the motor. Overcurrent can be caused by several problems such as short circuits and overworked motors. Protection devices such as fuses, circuit breakers, or electronic overload relays are used to turn off the power supply in the event of an overcurrent occurrence.

- Overvoltage and Undervoltage Protection: To stop too much current from flowing between the drive and the motor, Rockwell Automation AC drives include built-in overcurrent protection. Overcurrent can be caused by short circuits, overworked motors, and other flaws. Protection devices like circuit breakers, fuses, or electronic overload relays are used to switch off the power supply when an overcurrent situation happens.

Overtemperature Protection: AC drives generate heat as they operate, and too much heat can damage or even kill the drive’s internal parts. The drive is equipped with thermal sensors or temperature monitoring devices to prevent overheating.

These sensors keep an eye on the temperature and trigger safety mechanisms, such as reducing the drive’s output power, issuing alerts, or shutting it down, if it climbs over a safe threshold.

To sum up, an EMC filter is an essential component of an AC drive system that ensures EMC compliance and reduces electromagnetic interference. It protects the drive from external disturbances and helps screen other devices from the electrical noise the drive produces.

We are Asteam Techno Solutions Pvt Ltd: the go-to company for industrial automation products. We make a contribution to the circular economy by providing all industrial automation products for businesses and factories and also providing service work for them. We provide automation solutions with reputed brands including Allen Bradley, Mitsubishi, Phoenix Contact, Siemens, Schneider, Moxa, VIPA and more. Currently our staff members are serve a growing number of national and international customers each day.